The Vetipak site in Zeewolde is home to our successful long-term partnership with Bakker Logistics, part of the STEF group. It’s also where we work for Dynamic Products Factory, which develops creative products for the retail sector. We recently ensured that a multitude of party items in 3,300 displays reached their destinations with a well-known German retail chain. We joined forces to run the whole process from A to Z for D.P. Factory.

A day in the life of... Marijn van Houtum and Rene Hanenberg

Drawing, analyzing, 3D-printing.. It’s all daily practice for Marijn van Houtum en René Hanenberg. Marijn studies mechanical engineering at the Fontys University and does his internship at our Technical Engineering department. René recently started at Vetipak as Technical Engineer. This blog describes one of their working days.

7:15

The day starts. Marijn completes his design for an ergonomic improvement to insert products on the cardboard line. With this improvement the line operators will be able to work on a better and more natural way.

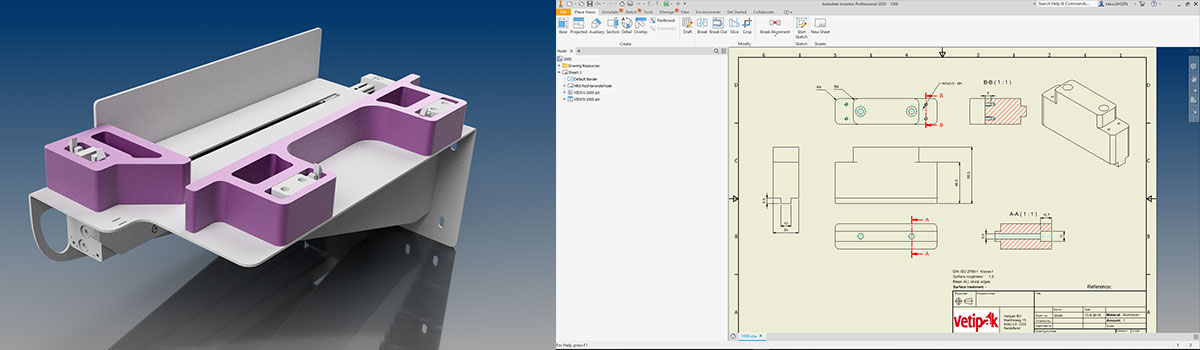

After some preliminary weeks of designing, making 3-D drawings and working on the solution Marijn is ready to finish it off. Today he draws all the parts in 2-D, accurate to the millimeter so our suppliers know exactly what they should produce.

7:30

René starts his day with a review. He is making an analysis of the machine interferences during the past week to see if there is a trend. This way we can set out preventive actions to avoid recurrence.

9:15

Time for coffee. I’ts always fun sitting around the table with the rest of the Vetipak Technichians. Of course we talk about work but certainly about football and other important matters ?

9:30

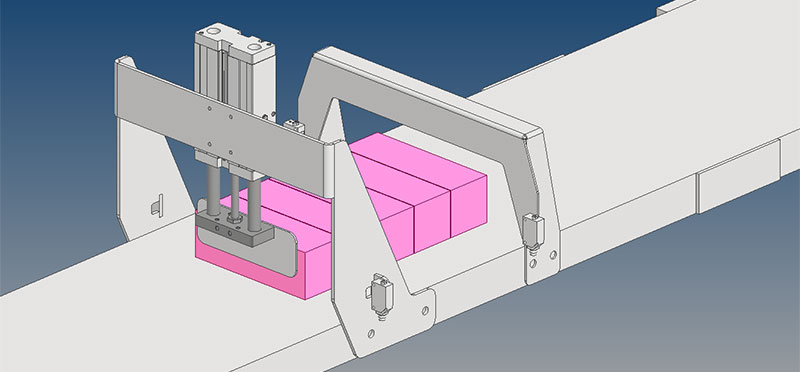

After the coffee break René starts to draw the robotarm in 3D. With this arm bags can be packed into cases. A very interesting development where he can puts his focus on. In the meantime Marijn works on one of his other projects.

11:00

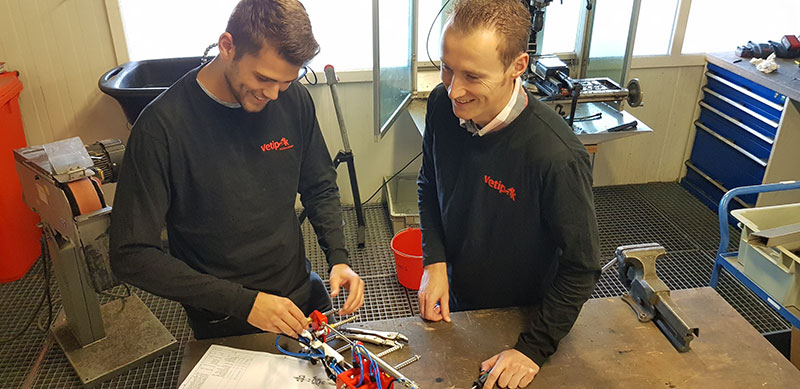

Short before noon we join forces; together we visit a test setup for a project where Niels Kanters, one of the Engineers of Vetipak, is working on. We do research on how to use a hopper to pack product into a card board box.

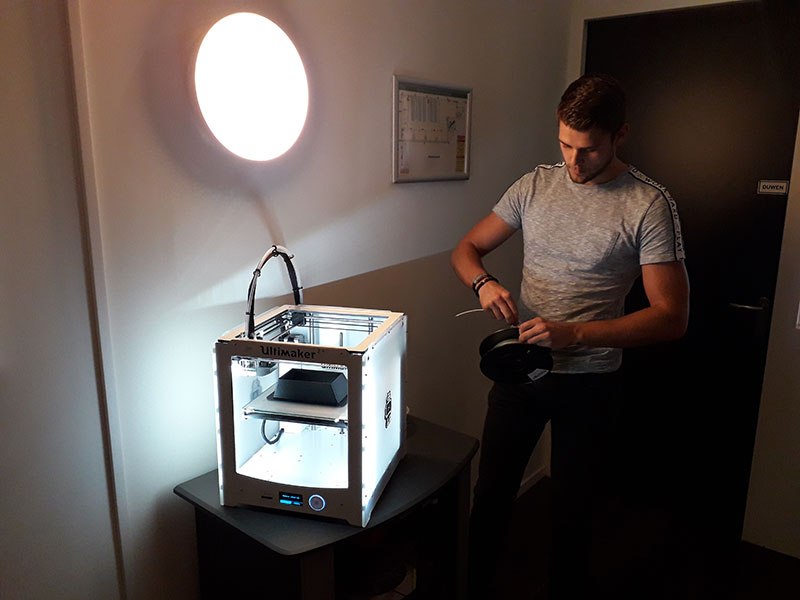

To save money and time we print the hopper in 3D. Marijn finds out that the printer is almost out of print material. To avoid failures he replaces the material, ready to continue the printing.

13:00

After lunch Marijn starts with the design of the output on one of many machines in the Vetipak factories. He made a test setup on the convear belt and the check weigher targeting on a constant flow of products in the middle of the belt. Finally Marijn decides to gather 5 boxes mechanically and works this out several in concepts.

14:30

Time to discuss the earlier worked out concepts together. We finally make the choice to use two sensors to count and group the products. The parts for this solution will be made from sheetmaterial.

15:30

A final complex job to finish the day off. Together we assemble the gripper for the robotarm. As we need to test some complex parts and on short notice we have been using the 3D printer again to print the parts. On this way we can have fast results.

16:30

Time to go home. It was a very intensive and fascinating Vetipak day again.