The Vetipak site in Zeewolde is home to our successful long-term partnership with Bakker Logistics, part of the STEF group. It’s also where we work for Dynamic Products Factory, which develops creative products for the retail sector. We recently ensured that a multitude of party items in 3,300 displays reached their destinations with a well-known German retail chain. We joined forces to run the whole process from A to Z for D.P. Factory.

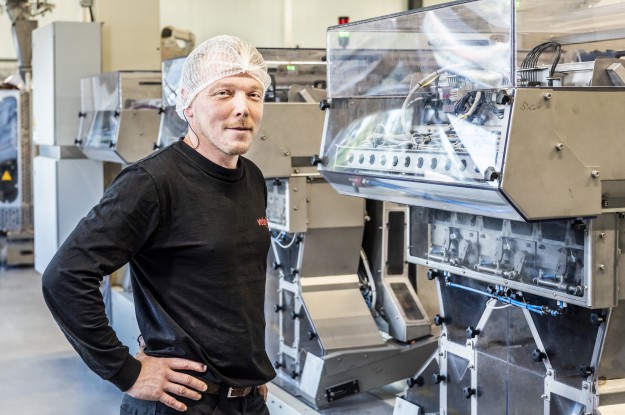

What drives... Jan van Diepenbeek

When you think of the word ‘passion’, a job at a packaging company may not be the first thing that springs to mind. That is, until our staff talk about what motivates them. Take Jan van Diepenbeek, Head of our Technical Services in Veghel. He’s very enthusiastic about the robot technologies we use in our production lines.

What exactly do you do at Vetipak?

“Together with a team of six technicians and an engineer, I’m responsible for our machinery in Veghel. We have a number of advanced packaging lines that use a lot of robot technology. Our main specialisation is in counting technology, which is the machine component that ensures the right quantity of products is packaged per unit, such as the number of sweets in a package. We’re also leading the way in cartoning technology, for example with our octagonal Celebrations party packaging.”

What does a typical day look like for your team?

“Our day usually begins with prioritisation and work distribution to ensure that everyone starts on the right task in the right place. We make thorough preparations together so that we have the right parts and tools with us. On occasion, we will need to travel elsewhere to make a repair. We also focus on developing new techniques and improving the existing lines.”

“Technical insight alone is no longer

sufficient for working here”

Jan van Diepenbeek,

Head of Technical Services

Vetipak Veghel

What's the best thing about your work?

“The complexity of our technologies, which has increased enormously in recent years. Having technical insight alone is no longer sufficient for working here. We’re frequently dealing with technologies that we’ve developed ourselves, in-house. Younger colleagues sometimes find that a little challenging, and experienced employees have to share their knowledge in the right way. At Vetipak, we prefer to do everything ourselves. Every year we develop a new machine that we build from scratch.”

And what’s your greatest challenge?

“Time and budget are always challenging factors. You also have to think ahead effectively. Most customers don’t want to invest in large orders right away when the packaging is new. They start out small and then expand, depending on the degree of success. We have to be able to anticipate this with our technology.”

Are there less enjoyable aspects to your job?

“Sometimes it takes quite a lot of effort to find the answer to questions we’ve been asked. Or something doesn’t go quite the way we wanted it to. I find that disappointing, because we always aim to excel here. Time pressure can also be troublesome. For example, new lines have to be ready for production within 20 weeks, and those weeks really fly past, I can tell you!”

“We always aim to excel here”

What are you most proud of?

“Last year we replaced the outdated counting technology in a number of lines with a completely updated version that we designed and built ourselves. We had to remove all of the controls for those lines and then rebuild them from scratch. We did it, and with a huge improvement in capacity to boot! We went from 50 deposits per minute to 70.”

Anything else?

“I’m also very proud of our team spirit. Everyone shares the same passion for machines. Most of us started out in production and ended up becoming technicians, purely because we were interested in doing so. That makes us a very close-knit team. And it says a lot about the Vetipak spirit that one of our technicians has recently returned after being away for three years. We have a lot of time for each other, and we’re only satisfied when we achieve the ultimate end result.”